NEWS

Vega Composites Signs a Joint Venture with Merlinhawk in the Presence of Her Excellency Dr. Neena Malhotra, Ambassador of India to Italy and San Marino.

Vega Composites has announced a significant expansion into India through a joint venture with Merlinhawk Aerospace Pvt Ltd, an Indian company specializing in aerospace and defense engineering, in the presence of Her Excellency Dr. Neena Malhotra, Ambassador of India to Italy and San Marino.

The agreement, signed at the Barberino di Mugello headquarters, entails the establishment of a production and design facility in the state of Tamil Nadu by 2025.

This move marks a pivotal step for Vega Composites following its acquisition by Gruppo Pasquali in 2021.

The joint venture, named Merlinhawk Composites, will focus on providing advanced solutions in composites, aiming to meet the growing demand in aerospace, maritime, land, railway, hydrogen storage, and fuel cell sectors in India and Southeast Asia.

This development strengthens Vega Composites' positioning in international markets and promises significant business and growth opportunities.

Read more: https://t24.ilsole24ore.com/art/vega-composites-gruppo-pasquali-joint-venture-per-lindia

Gruppo Pasquali has been working diligently over the least three years to develop and implement an internationalization plan for the US and North American markets. In preparation of this effort, Pasquali Microwave Systems was hosted by Alabama Department of Commerce, Small Business Liaison Offices of Alabama, Huntsville/Madison County Chamber, North Alabama International Trade Association, the Port of Huntsville and the Invention to Innovation Center (I2C) June 27th – 29th, 2022. The culmination of these meetings led to signing a partnering agreement with Fighter Link Solutions International and then an open house at the I2C on June 20th.

“We are very excited to finally embark on this next chapter of the Company’s history, and look forward to forming long-standing partnerships” Roberto Lapini – CEO of Gruppo Pasquali.

Pasquali Microwave USA selects VOSB to Enter North American Markets

"Huntsville, AL – June 21, 2023 – Gruppo Pasquali, has selected Fighter Link Solutions International to implement and execute its expansion plans into the United States and North American markets under Pasquali Microwave USA. This effort began more than four years ago with the establishment of Pasquali Microwave USA. After an initial period to understand the American market, it was decided that the state of Alabama would be the right starting point for Pasquali Microwave USA business. It was hosted by the Alabama Department of Commerce and several Alabama state agencies to discuss common projects and opportunities in the Aerospace, Defense & Space and Civil sectors located in Huntsville, Alabama.

The strategic collaboration between Fighter Link and Pasquali Microwave USA represents a significant milestone for both companies, marking their commitment to fostering international partnerships and expanding their reach in the defense and technology sectors. This partnership brings together the expertise, resources, and innovative capabilities of two leading small businesses poised to deliver groundbreaking solutions in high-tech manufacturing and equipment supply to meet the evolving demands of the Defense & Space industry.

Read a full report on the event on the FLSI site here.

About Fighter Link:

Fighter Link Solution International is a veteran-owned small business based in Huntsville, Alabama. Fighter Link focuses on delivering innovative solutions to the Defense & Space industry, specializing in fleet sustainment, IETM development, and Source Approval Requests.

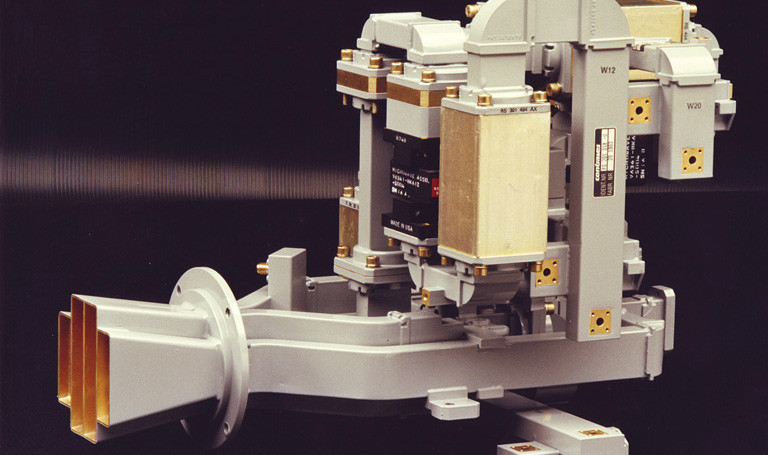

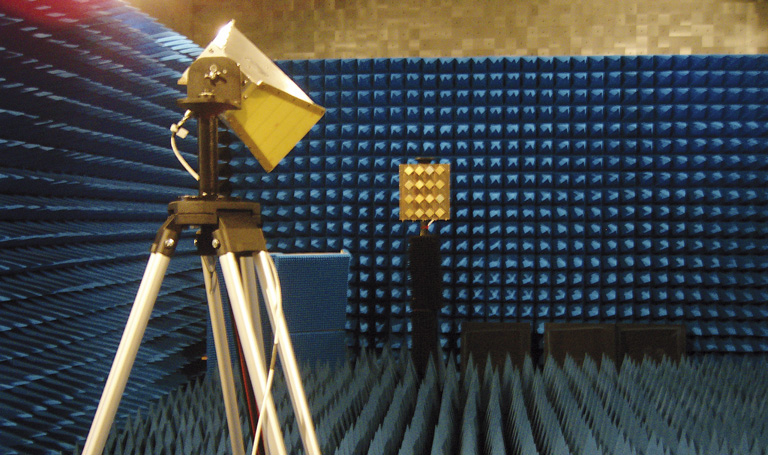

Five companies organized for join and integrate their competences for developing high-quality custom solutions with special electrical and mechanical requirements.

Design |

Manufacturing |

Test |

| cutting-edge EM simulation tools and CAD/CAM systems | assisted automated machines and specialized equipment | dimensional and functional performance verification |

A full control over the entire production cycle, guarantees high quality in GRUPPO PASQUALI’s microwave products.

Group’s Companies

The US Division of Gruppo Pasquali has been established to offer commercial and technical assistance to our US-based customers. Since providing timely support to customer queries is considered a key aspect of Gruppo Pasquali's approach to customer service, the US department ensures direct assistance, working across different time zones from the Italian headquarters.

Located in Washington DC, in 2023, Pasquali Microwave USA expanded by adding a new Sales Representative office in Huntsville, AL – the beating heart of the Space & Defense industrial and research community.

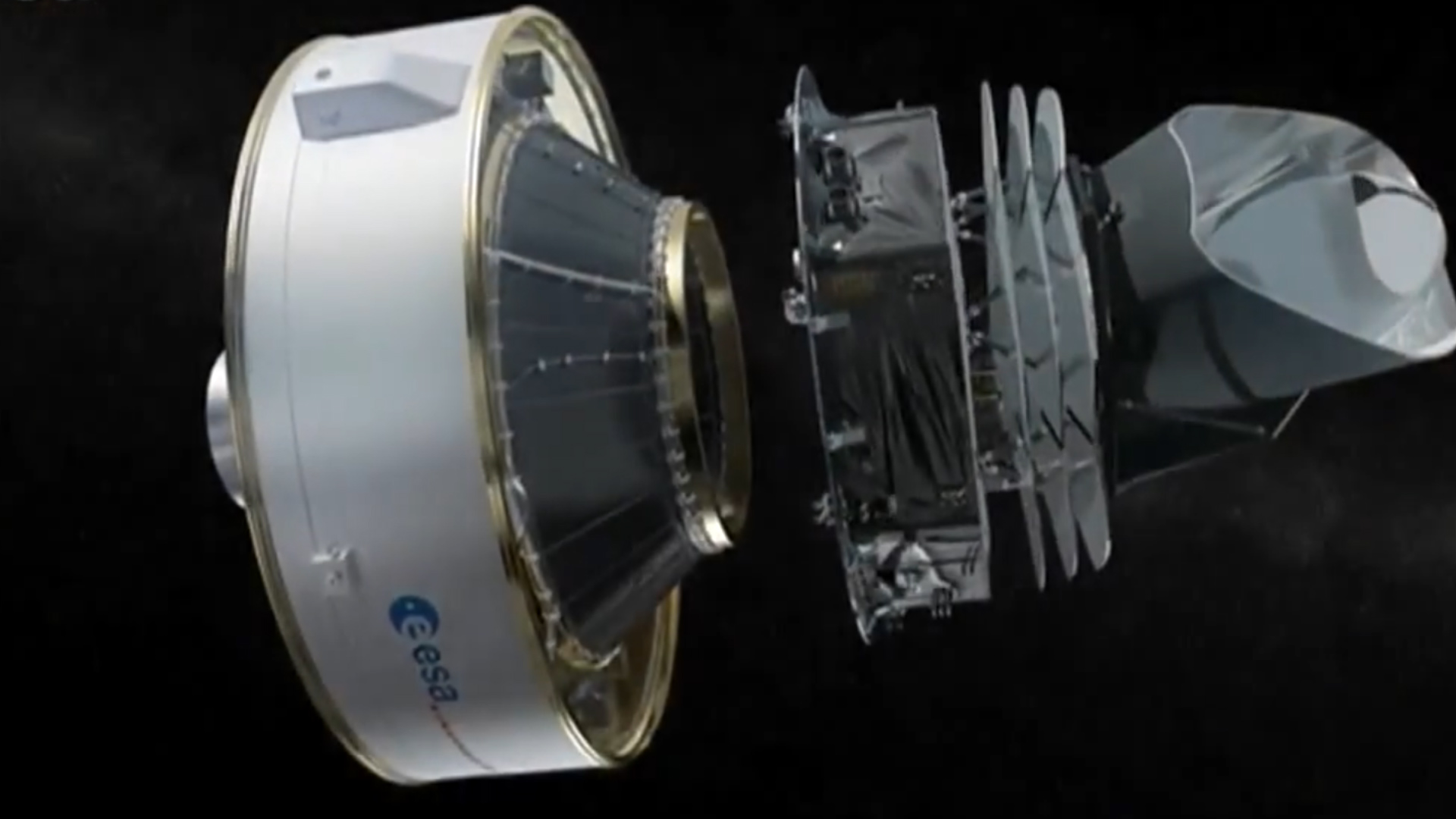

SPACE

CIVIL

DEFENCE

NAVAL

General Group information and Investment policy

Employees on Gruppo Pasquali

Production Area

Investments

Gruppo Pasquali's Quality System is ISO 9001:2015 certified.

All companies within the Group are also certified to the UNI EN 9100:2018 Quality System.

Obblighi informativi per le erogazioni pubbliche:

Gli aiuti di Stato e gli aiuti de minimis ricevuti dalla nostra impresa sono contenuti nel Registro nazionale degli aiuti di Stato di cui all’art. 52 della L. 234/2012 a cui si rinvia e consultabili al seguente link: https://www.rna.gov.it/RegistroNazionaleTrasparenza/faces/pages/TrasparenzaAiuto.jspx